1. What is Two-Photon Direct Laser Writing (DLW)?

Two-photon direct laser writing (DLW) is 3D printing for the microscopic world. This techniques goes beyond the smallest shapes and sizes that can be accomplished by garden variety 3D printing. The highest resolution that can be achieved by DLW is typically few micron to sub-micron range. To put this into perspective, the average human hair has a cross section of 70-100 μ. So imagine 3D structures cozily sitting by the dozen across the cross-section of a hair. This technique allows 3D drawing of complex shapes with fine features (μ to few nm). The complexity of shapes that can be achieved by this technique are limited only by photochemistry of materials used for fabrication, and the limits of the optical setup. The vesatility of this technique has led to fabrication of complex art forms at microscopic scales like the ones seen here.

2. How Does Diretct Laser Writing (DLW) Work?

(a) High Spatial Resolution

DLW technique is based on very specific photochemical reactions set off at in a small area in the middle of the focussed laser beam, see Figure 3. The reaction is confined to such small areas due to high spatial resolution of two-photon absorption (TPA). TPA depends on the square of the intensity of light, this means that it rapidly decreases with decreasing intensity of laser. The difference between the linear one-photon flourescence and non-linear two-photon fluorescence can be seen in Figure 3. When a UV laser is focused on a solution containing a UV absorbing molecule in Figure 3(a) the resulting green fluorescence can be seen throughout the path of the laser within the solution, this is beacause of the linear nature of one-photon (or normal) absorption. However when a high power IR laser is focused on the same sample two-photon absorption occurs is a very small focal volume as seen in Figure 3(b) (also see inset). Two-photon absorption is confined only to the focus of the laser because it is a non-linear optical phenomenon and occurs at high laser intensities which can be found only at the focus of the laser. This high spatial resolution is key to for the use of two-photon induced processes to achieve DLW.

(b) Different Photochemical/Photophysical Processes in Direct Laser Writing (DLW)

This highly localized flourescence can be used to initiate spatially confined polymerization [1]. Other photochemical phenomenon that can be triggered by TPA include, two-photon photoreduction [2-3], two-photon induced melting of nanoparticles [4], and two-photon ablation [5]. A photoactive medium for fabrication of microstructures by DLW can function through one or more of the different photochemical process described above. A photoactive medium can be organic materials like oligomers, or inorganic materials like solutions of metal salts or nanoparticles. In principle you take a photoactive liquid precursor on a subrtate such as glass or silica and write three-dimensional (3D) structures in them by three-dimensionally manipulating a focused laser inside them. This is exactly what is done by a DLW fabrication system.

(b) Voxels and Construction of 3D Structures in Direct Laser Writing (DLW)

The photoactive region at the focus of a tightly focused laser beam has a prolate spheroidal shape, often this shape is replicated (imaged inside) inside the photoactive medium through photochemical reactions. The prolate spheroidal shape forms the fundamental building block of a 3D structure in DLW and is called a volume pixel (voxel). Three dimensional microstructures can be construcrted by manipulating the position of the focus inside the photoactive medium and placing multiple voxels in close proximity so as to induce their overlap[6],as seen in Figure 4. The free volume left between two voxels after their overlap is filled over due to polymerization induced by diffusion of active species from the centre of the laser focus.

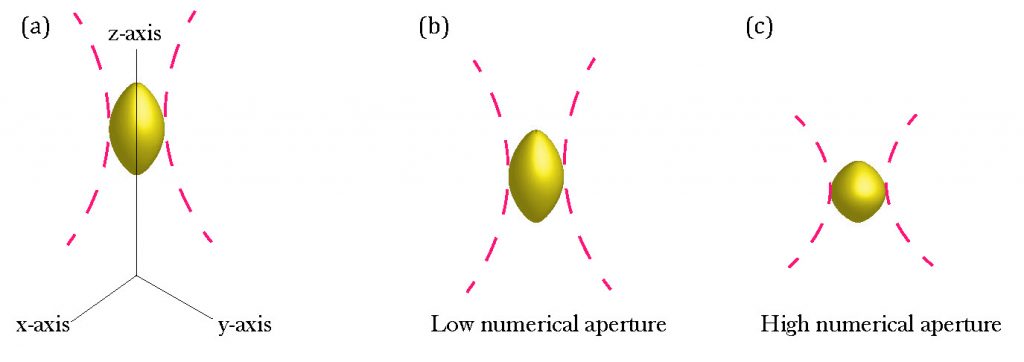

(b) High Resolution Vs Low Resolution in Direct Laser Writing (DLW)

A three-dimensional structure is thus nothing more than a repetetion of voxels merged in space. The prolate speroidal shape of the voxel means that the voxel dimensions are greater along the Z- axis than in the XY plane as seen in Figure 6. The Z-axis is taken as the direction of propagation of the laser within the sample. The size of the voxel formed depends on the lens used to focus the laser on to the sample during fabrication. A high numerical aperture lens gives tighter focus inside the photoactive medium and hence a smaller voxel as seen in Figure 6 (b)-(c). Smaller voxels in turn lead to higher resolutions during microfabrication.

References

[1] LaFratta, C. N., Fourkas, J. T., Baldacchini, T., & Farrer, R. A. (2007). Multiphoton fabrication. Angewandte Chemie International Edition, 46(33), 6238-6258.

[2] Kaneko, K., Sun, H. B., Duan, X. M., & Kawata, S. (2003). Two-photon photoreduction of metallic nanoparticle gratings in a polymer matrix. Applied Physics Letters, 83(7), 1426-1428

[3] Park, J. J., Bulliard, X., Lee, J. M., Hur, J., Im, K., Kim, J. M., … & Lee, T. W. (2010). Pattern Formation of Silver Nanoparticles in 1‐, 2‐, and 3D Microstructures Fabricated by a Photo‐and Thermal Reduction Method. Advanced Functional Materials, 20(14), 2296-2302.

[4] Son, Y., Yeo, J., Moon, H., Lim, T. W., Hong, S., Nam, K. H., … & Ko, S. H. (2011). Nanoscale electronics: digital fabrication by direct femtosecond laser processing of metal nanoparticles. Advanced Materials, 23(28), 3176-3181.

[5] Yamasaki, K., Juodkazis, S., Watanabe, M., Sun, H. B., Matsuo, S., & Misawa, H. (2000). Recording by microexplosion and two-photon reading of three-dimensional optical memory in polymethylmethacrylate films. Applied Physics Letters, 76(8), 1000-1002.

[6]Lee, K. S., Kim, R. H., Prabhakaran, P., Yang, D. Y., Lim, T. W., & Park, S. H. (2007). Two-photon stereolithography. Journal of Nonlinear Optical Physics & Materials, 16(01), 59-73.